Why Use A Water Jet Cutting System:

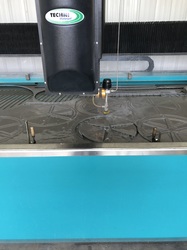

Speed of Production – With our automated process and state-of-the art machine, we can rapidly produce parts and components from virtually any material. This is much faster than conventional machining.

Quality manufacturing – Our computer-controlled cutting assures quality manufacturing. Parts can be cut to exacting tolerances and into any shape. Water jet cutting works for both small and large parts. The close part-nesting assures maximum material yield with minimal waste with tolerances of +-.005”

Price control – The ability to stack and rapidly cut materials and use an automated process typically delivers a lower cost than conventional machining or fabricating. This is especially true for high-volume production.

Material – We can cut soft materials such as cork, rubber and plastics for gaskets, parts and components. The fine cutting stream will not cause rough or torn edges on these materials and the ability to stack material sheets provides tremendous production efficiency. Hard materials such as steel, aluminum, wood, stainless steel, and granite are easily cut with the water jet process with a clean, smooth edge or surface.

Speed of Production – With our automated process and state-of-the art machine, we can rapidly produce parts and components from virtually any material. This is much faster than conventional machining.

Quality manufacturing – Our computer-controlled cutting assures quality manufacturing. Parts can be cut to exacting tolerances and into any shape. Water jet cutting works for both small and large parts. The close part-nesting assures maximum material yield with minimal waste with tolerances of +-.005”

Price control – The ability to stack and rapidly cut materials and use an automated process typically delivers a lower cost than conventional machining or fabricating. This is especially true for high-volume production.

Material – We can cut soft materials such as cork, rubber and plastics for gaskets, parts and components. The fine cutting stream will not cause rough or torn edges on these materials and the ability to stack material sheets provides tremendous production efficiency. Hard materials such as steel, aluminum, wood, stainless steel, and granite are easily cut with the water jet process with a clean, smooth edge or surface.